Refurbishment is an important element of a resource-efficient manufacturing process and a key concept within the circular economy. By keeping products, components or materials in a closed-loop supply chain as long as possible, raw material use, energy usage and emissions can all be significantly reduced. The refurbishment concept is sometimes confused with remanufacturing or re-usage of products. Lack of clarity in the definition of the terms ‘used’, ‘refurbished’ and ‘remanufactured’ can cause confusion. So, let’s take a closer look into the refurbishment concept!

Re-usage of assets

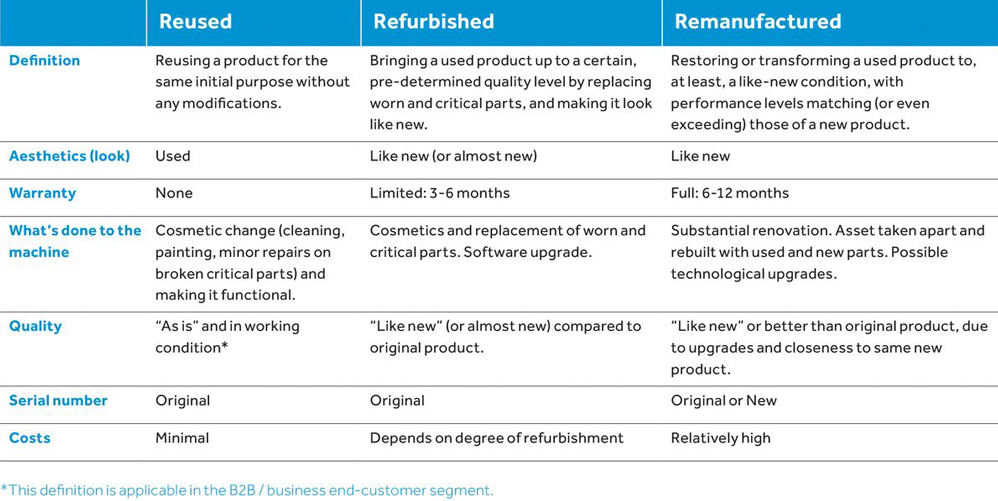

“Reused” can be defined as simply reusing a product that has been cleaned but otherwise not undergone any modifications. A reused product, or its components, is put back into use for the same purpose for which it was originally designed. In the world of capital goods, manufacturers, dealers and resellers define reuse as ‘selling on an “as is” basis’.

Refurbished assets

“Refurbishment” can be defined as bringing used products up to a certain, pre-determined, quality standard. It involves the replacement of worn and critical parts, and aesthetically making the product look like new. The level of refurbishment and “like newness” depends on various factors, such as the manufacturer’s and the industry’s standards, the asset type, and relevant technological advancements. A refurbished asset may have limited improvements to functionality and slight malfunctions may be acceptable. It usually entails no changes to the original design and only a limited warranty is offered.

Remanufacturing of assets

“Remanufacturing” can be described as the process of acquiring and restoring or transforming used products (i.e. non-functioning, discarded or traded-in products) to, at least, a like-new condition, with matching performance levels and (usually) a warranty equal to that of a new product. This means taking the entire product apart and replacing all worn parts. Remanufacturing can include technical upgrades (of both hardware and software) and changes to the original design. To make a clear distinction within the portfolio, remanufactured assets may be assigned a new serial number. Remanufacturing is overall costlier than refurbishment, and generally considered to be as good as new; or even better than the original thanks to, for example, upgrades.