The expectation is that in the coming years, more manufacturers will start to develop refurbishment capabilities, leading to increased volume in refurbished asset sales*. There are variable aspects that need to be considered to establish a sustainable and profitable refurbishment business.

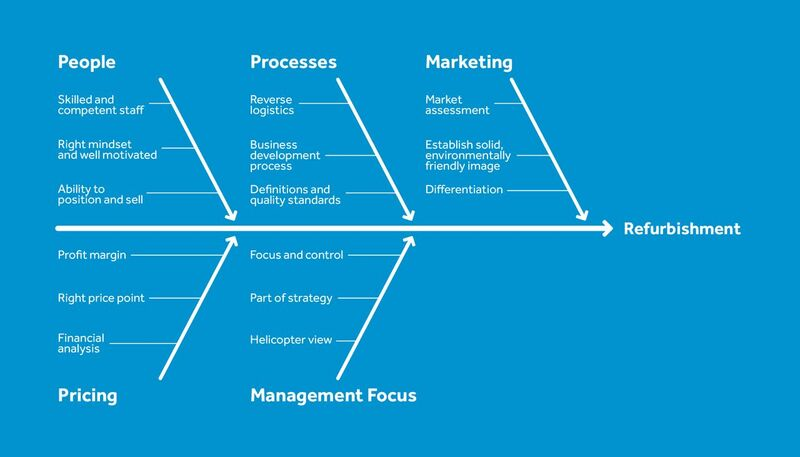

Figure: The organizational elements identified as critical in assessing the feasibility of the refurbishment business.

Figure: The organizational elements identified as critical in assessing the feasibility of the refurbishment business.

People

Before embarking on refurbishment, a manufacturer needs skilled, competent staff who are knowledgeable, have the right mindset and are well-motivated. You also need people who can position the equipment and sell it to the market. Selling refurbished equipment is a different and sometimes more cumbersome process than selling new equipment. It can also be given a spur by having the right sales incentives for refurbished assets.

Processes

Setting up a good reverse logistics process is critical for return flows but also for to-be-recycled products. A manufacturer should consider how they can retrieve the resources and products they want to refurbish, approaching this resource challenge from the beginning of the product or component’s life cycle. These return flows should be sustainable and can come from trade-ins or buy-backs. Typically, still relatively little attention is given to this process in most countries and industries.

As a manufacturer, you should also look at the entire business development process, from the beginning to the end of a product or machine’s life. The process of refurbishment should be as controlled as possible. Definitions and standards also need to be established, and continuously improved through learning, customer feedback and benchmarking against other OEMs. Standards need to be adaptable because circumstances and customer requirements change, and experience evolves.

(Re-)Marketing

Before setting up refurbishment, a manufacturer should assess its market. Read market studies, determine market size and segments, look at growth potential and possible competitors (who can be OEMs or third parties). Legislation should also be checked, as it can differ per country and market. There is little point in trying to push refurbished assets at the wrong customer base. So perhaps the most critical element of this assessment is checking beforehand who your customers are, and mapping their demands and needs, including their motivation to buy refurbished instead of new.

Manufacturers should also establish a solid, environmentally-friendly brand image to maintain and create trust amongst customers. Finally, refurbished assets should be well differentiated to prevent cannibalization of new assets. It should also be transparent what the actual differences are compared to new assets, so that customers have the right expectations, can make informed decisions and are ultimately more likely to be satisfied with their product.

Pricing

Refurbishment can contribute significantly to additional sales. Setting the right price-point is a very important element, as is setting a limit to the costs involved in refurbishment. One way to establish the right price-point is to develop a business case and determine if it makes sense and is feasible. At the same time, the set price-point must of course be acceptable to your customers.

Management focus

It is also key to have focus at management level: from board level down, refurbishment should be part of top management strategy, and leaders and managers should think of refurbishment as a key strategic choice. Having adopted a helicopter view across the entire operation, top management should identify the right strategy and vision, and then ensure that this is communicated and trickled down to all levels of the company.

Role of leasing

Leasing can further stimulate the refurbishment processes of manufacturers, both by helping them keeping a grip on their assets and by optimizing an asset’s value through multiple life cycles. Provided they have an efficient recovery and refurbishment process in place, companies can benefit from a second- or third-income stream on next-life materials and products.

Research and insights

DLL’s whitepaper ‘Refurbishment: the road to success’ deepens the understanding of the refurbishment concept and provides a checklist to manage the process of setting up a refurbishment business. Get your free copy of the whitepaper now.